Vectran® (LCP): Strength & Flex Fatigue

Key Features of Vectran® LCP:

- High strength to weight ratio

- Good creep resistance

- High abrasion resistance

- Good flex fatigue properties

- Minimal moisture absorption

- Excellent chemical resistance

History

First produced in 1990, Vectran® is the only commercially available melt spun LCP fiber in the world.

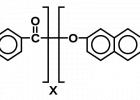

Composition

Vectran® is an aromatic polyester spun from a liquid crystal polymer in a melt extrusion process. This process orients the molecules along the fiber axis, resulting in a high tenacity fiber.

FIBER-LINE® Enhancing Processes for Vectran®:

FIBER-LINE® Vectran® Products:

Manufacturer

Kuraray™

Common Types & Deniers

HT: High Tenacity

UM: Higher Modulus/Lower Elongation

NT: Medium tenacity

Deniers: 200, 400, 750, 1000, 1420, 1500, 2250

Vectran® (LCP) Bare Fiber Performance

CHEMICAL COMPATIBILITY

Chemical Resistance to Acid: Stable to acids <90% concentration.

Chemical Resistance to Alkali: Stable to alkalis <30% concentration.

Vectran® (LCP) Data

Standard Modulus

| Property | UOM | Value |

|---|---|---|

| Breaking Tenacity | g/d | 23.0 |

| Specific Gravity | Ratio | 1.40 |

| Elongation @ Break | % | 3.8 |

| Tensile Modules | g/d | 600 |

| Moisture Regain* | % | <.1 |

| Creep** | % | <0.4 |

| Skrinkage*** | % | <0.20 |

| Melt Point | ℃ | 350 |

High Modulus

| Property | UOM | Value |

|---|---|---|

| Breaking Tenacity | g/d | 30.0 |

| Specific Gravity | Ratio | 1.40 |

| Elongation @ Break | % | 2.8 |

| Tensile Modules | g/d | 830 |

| Moisture Regain* | % | <0.1 |

| Creep** | % | <0.4 |

| Shrinkage*** | % | <0.20 |

| Melt Point | ℃ | 350 |

* Equilibrium moisture regain @ 55% RH ** Creep @ 40%-58% ultimate tensile strength *** Shrinkage in dry air @ 177 C for 30 minutes

This data is provided for informational purposes only, and does not constitute a specification. FIBER-LINE makes no warranty, express or implied, that the product conforms to these values. Contact your FIBER-LINE representative for exact product details which conform to your specific requirements.