PET Polyester: Versatile & Ideal For Coatings

Key Features of PET Polyester"

- Good chemical resistance

- Hydrophobic

- Good abrasion resistance

- Good tensile strength

History

PET is the most common thermoplastic polymer in the polyester family. The first US commercial polyester fiber production was completed in 1953 by DuPont™ under the name Dacron®. It is the same polymer resin utilized in the plastic bottle industry.

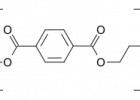

Composition

PET is produced in a melt spun and drawing process. The three processes utilized in the production of PET fiber are polymerization, melt-spinning, and drawing or hot stretching the fibers based upon their elongation requirements.

FIBER-LINE® Enhancing Processes for PET:

FIBER-LINE® PET Polyester Products:

Manufacturers

Fiber-Line® works with a variety of PET Polyester suppliers

Common Types & Deniers

High Tenacity

Standard Shrink

Low Shrink

Ultra-low shrink

Deniers: 50-3000

PET Polyester Fiber Bare Fiber Performance

PET Polyester Fiber Data

High Tenacity

| Property | UOM | Value |

|---|---|---|

| Breaking Tenacity | g/d | 9.3 |

| Specific Gravity | Ratio | 1.38 |

| Elongation @ Break | % | 14.6 |

| Tensile Modules | g/d | 120 |

| Moisture Regain* | % | 0.4 |

| Creep** | % | 1.0 - 12.0 |

| Skrinkage*** | % | 8.0 - 15.0 |

| Melt Point | ℃ | 256 |

Low Shrink

| Property | UOM | Value |

|---|---|---|

| Breaking Tenacity | g/d | 8.4 |

| Specific Gravity | Ratio | 1.38 |

| Elongation @ Break | % | 19.5 |

| Tensile Modules | g/d | 70 |

| Moisture Regain* | % | 0.4 |

| Creep** | % | 1.0 - 12.0 |

| Shrinkage*** | % | 3.0 - 8.0 |

| Melt Point | ℃ | 256 |

* Equilibrium moisture regain @ 55% RH ** Creep @ 40%-58% ultimate tensile strength *** Shrinkage in dry air @ 177 C for 30 minutes

This data is provided for informational purposes only, and does not constitute a specification. FIBER-LINE makes no warranty, express or implied, that the product conforms to these values. Contact your FIBER-LINE representative for exact product details which conform to your specific requirements.