Nomex® Meta-Aramid: Heat & Flame Resistant

Key Features of Nomex® Meta-Aramid:

- Excellent heat & flame resistance

- High chemical resistance

- Low thermal shrinkage

- Self-extinguishing flame retardant properties

- Soft-hand yields good textile properties

History

Originally called HT-1, Nomex® was first developed in the 1960’s and made commercially available in 1967 by DuPont™. It was first used as fabric for race-car driver suits.

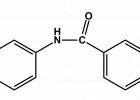

Composition

Similar to Kevlar®, Nomex® is an aromatic polyamide. The “Meta” linkage position of the aromatic groups differs from that of Para-Aramids. The chemical bonds are zig-zag in configuration, resulting in a lower tensile and modulus fiber compared to Kevlar®.

Nomex® is flexible and higher in elongation however, making it an ideal textile yarn for fabrics.

FIBER-LINE® Enhancing Processes for Nomex®:

FIBER-LINE® Nomex® Products:

Manufacturer

DuPont™

Common Types & Deniers

T-430: Filament Yarn

Deniers: 200, 1200, 1600, 2400

Nomex® Meta-Aramid Bare Fiber Performance

CHEMICAL COMPATIBILITY

Chemical Resistance to Acid: Strength loss in H2SO4 below acid dew point.

Chemical Resistance to Alkali: Good at room temperature but degraded by strong alkalis at high temp.

Nomex® Meta-Aramid Data

Standard Modulus

| Property | UOM | Value |

|---|---|---|

| Breaking Tenacity | g/d | 5.0 |

| Specific Gravity | Ratio | 1.38 |

| Elongation @ Break | % | 30.0 |

| Tensile Modules | g/d | 125 |

| Moisture Regain* | % | 4.5 |

| Shrinkage*** | % | .4 |

| Melt Point | ℃ | N/A |

* Equilibrium moisture regain @ 55% RH ** Creep @ 40%-58% ultimate tensile strength *** Shrinkage in dry air @ 177 C for 30 minutes

This data is provided for informational purposes only, and does not constitute a specification. FIBER-LINE makes no warranty, express or implied, that the product conforms to these values. Contact your FIBER-LINE representative for exact product details which conform to your specific requirements.